In a bid to accelerate indigenous manufacturing and production, India Inc has recently been giving increasing importance to the semiconductor industry, which has far reaching demand and opportunities. While the country is excelling in the design aspect, manufacturing is still a long way off, handicapped by a shortfall in manpower and appropriate skilling. In a conversation with DH's Anjali Jain, India Electronics and Semiconductor Association (IESA) CEO and President K Krishna Moorthy touched upon the shortfalls in India's chipmaking endeavor, the strides it has made in recent years and what lies ahead for the industry.

Can you elaborate on the importance of semiconductors and where India stands in this industry?

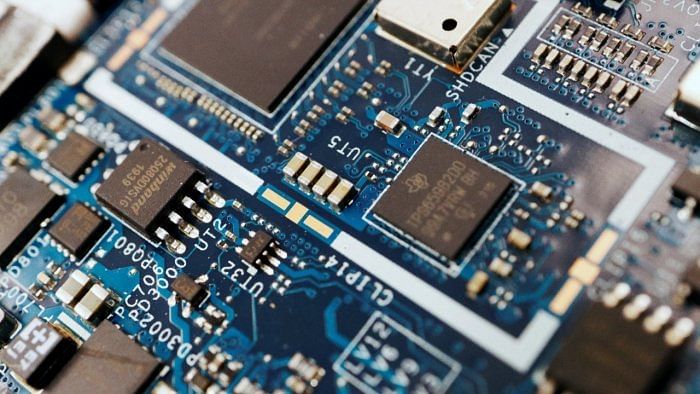

The semiconductor is the basic building block critical for any electronic system, whether it is space or defence or consumer electronics or automotive. Today we have achieved a certain amount of self reliance in passive electronics like resistors, capacitors, relays. There are many companies in India now for those products. But when it comes to active semiconductors, that is transistors, complex integrated secure systems on chips, or power semiconductors, we don't have any manufacturing capability in India.

But the design capability in India has become almost on par with all the leading countries in the world. Probably 20%-22% of the design engineers in the world are in India and 1/5th of the design community is in India. In fact, many multinational companies are getting the designs for their country's defence and space out of India.

Why do you think there is a lag in manufacturing of active semiconductors in India?

The number one reason is the amount of investment required. Until now, no country in the world has gone into high volume complex semiconductor manufacturing without government involvement. Today, the GOI says it will fund 50% of the investment that is required for semiconductor manufacturing. On top of that 20-25% is offered by different states by adding subsidies for assembly or infrastructure creation and audit. About 25-30% from foreign technology partners and the gap, if any, can be raised as debt.

The second reason why it has not happened so far is a lack of availability of technology due to shortfalls in R&D investment. Where advanced technologies are available, those countries and companies will not give you access to the technology because that is where they make money. Now, the government has provided $1 billion of incentives for R&D companies’ product development, in the form of design linked incentives, which is a huge commitment. And the universities are setting up R&D fabrication units, which is an absolutely new thing that's happening in the country. But it may take another three years from now when we will start seeing a lot more products coming out of India and also manufacturing happening.

What are some of the reforms that you would like to see to facilitate growth even further?

India is probably going to get into a difficulty on the availability of quality talent. If we're going to grow business by 10x, we need top class engineers. India is producing engineers, but the quality is not of that calibre which can be directly employed immediately. So the companies have to spend millions of dollars training them and making them understand the fundamentals. We need to significantly upscale the technical education system. The government should really push the New Education Policy in such a way that the quality of education in our schools and engineering colleges becomes top class, like everywhere else in the world.

Since Covid and the war in Ukraine have caused a lot of supply chain issues, when and how will we return to normalcy?

Earlier just after Covid, the delivery cycles were as high as two years. Now it has come down to a very reasonable timeframe, not exactly back to normal, but memory chips and many of the components are available immediately. Others are almost getting there. By the end of June or second quarter of this calendar year, or latest by September of this year, we should see everything back to normal as the demand has also normalised. And with the economic slowdown and high inflation in the US and Europe, the demand for non essential products, particularly in consumer electronics has come down. So, that also is easing up the supply chain for India.