Pottery making is probably one of the oldest traditional Indian handicrafts. It is an exclusive craft where agile hands turn lumps of rustic earth into an assortment of elegant utility and decorative articles.

At Bengaluru’s Benson Town there is a settlement of potters. The locality called Pottery Town. Their ancestors were classic potters hailing from various parts of Karnataka and neighbouring Tamil Nadu and Andhra Pradesh and were chosen by the Mysore Wodeyars to work for them. This was about 150 years ago and their legacy still lives on. At present, you can find the third, fourth and fifth generations of potters here. About 50 families reside here and over 150 artisans follow the pursuit. Skill runs in their blood and they initiate work at an early age, hence they typically attain expertise by adulthood.

Various stages

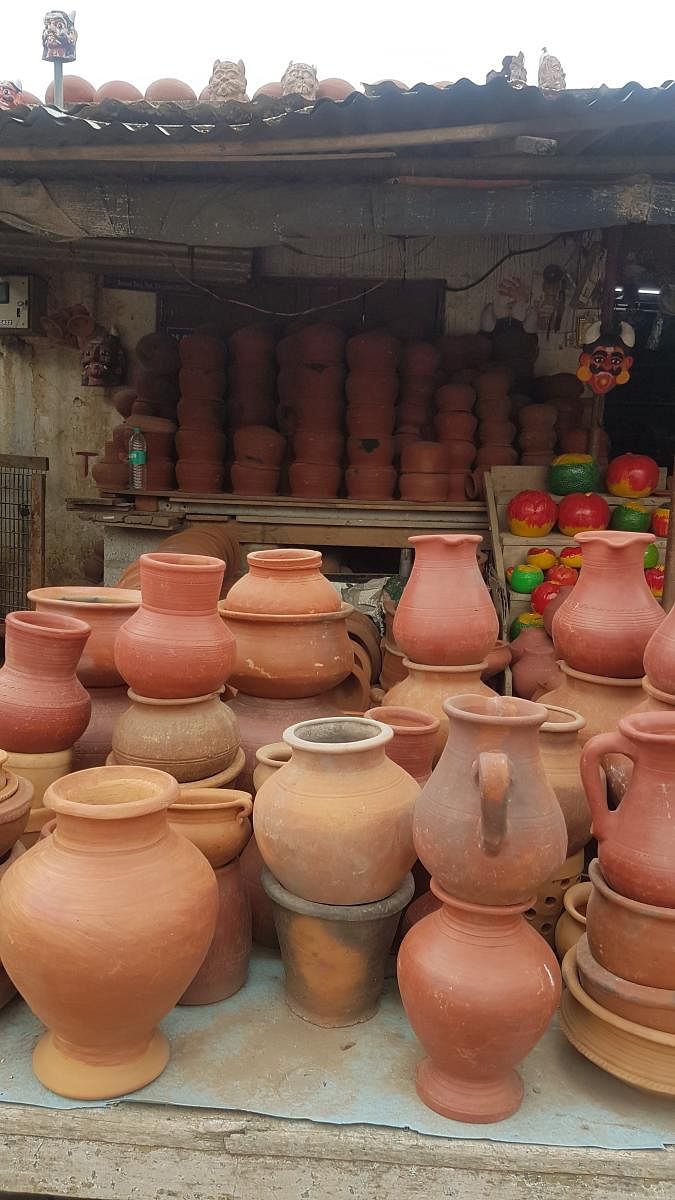

A walk down the street reveals arrayed earthenware in different stages of making. There is a line of retail stores which altogether form the licensed wholesale pottery market. Except for certain ingenuous designs and use of the electric wheel instead of the hand wheel, nothing much seems to have changed from the original process. The clay is procured from the lake beds near Tumakuru, Hoskote, Hennur and other surrounding areas. The dry mud has to be soaked in water for two days after which it is cleaned and thoroughly kneaded because of which it acquires its suppleness. The prepping is crucial and makes the clay feasible to work on.

The potters get accustomed bulk orders from hotel and restaurant owners, plant nurseries and domestic users. A host of items are produced based on demand. For the most part, they are into the making of kitchenware. Different types of cups are moulded, these range from chai kullads to lassi cups, ice cream or kulfi cups and the ones used for matka biriyani. A variety of platters, huge tandoor pots and other utensils are also made.

The insistence on kitchenware has risen considerably after the plastic ban which has come as a blessing to the artisans as well as the environment. And not to mention the bliss of the earthy flavours imparted to the dish cooked and served in pots. Besides kitchenware, garden pots of various sizes and shapes are also made.

Using an electric wheel, a potter can make up to 2,000 small pieces per day. Fresh pieces are aligned in rows upon wooden planks and let out to dry. It takes a day or two for them to be fully dried after which they are fired in a brick kiln. Firing renders a pleasing colour and a fine finish to the pots. Considering the meticulous steps that go into pottery making, it is apparent that there has to be a collaborative effort. For this venture to work, mutual cooperation among family members is very important.

Sixty-year-old Mallika has been making a livelihood in this vocation since childhood. Her son, daughter-in-law and daughter all work together. “I even encourage my grandchildren,” she says from the compact room that serves as their manufacturing unit. For many artisans, their outlet itself doubles up as the working zone.

Before the Ganesha festival, the artisans make eco-friendly idols of Goddess Gowri and Lord Ganesha. Wet clay is poured into the mould and after demoulding, minor defects are rectified and the idol is dried for some days and then handpainted. Organic colours and watercolours are used. In the festive season, an average family could assemble about 5,000 idols. Come Deepavali, the Pottery Town bustles again with the mass production of earthen lamps. The artisans fabricate more than 400 types of lamps every year. During Christmas, there is a demand for crèche sets too.

Further, creative craftspeople even make artistic interior and exterior pots, sculptures and ornamental pieces. “We can sustain on regular orders, but we take customised landscaping orders also,” says artisan G Rajashekhar who is a recipient of a state government award. Since 42 years, he has been committed to this field. An exceptional innovation by him is the inclusion of activated carbon in clay idols. When immersed, they can cleanse the water bodies and if employed on a large scale can actually make a difference, he says.

Looking forward

The potters in Pottery Town not only uphold their tradition but are keen on boosting their environs as well. They do face challenges. There is a threat of air pollution from the smoke emitted while firing the pots. Lack of space is yet another crisis due to which some potters have relocated to the suburban places. Generally speaking, they seem to be contented although they would prefer substantial government support. As for us, as responsible citizens, it is time to shift from plastic and other synthetic materials to eco-friendly items and make sincere efforts to embrace eco-friendly ways.